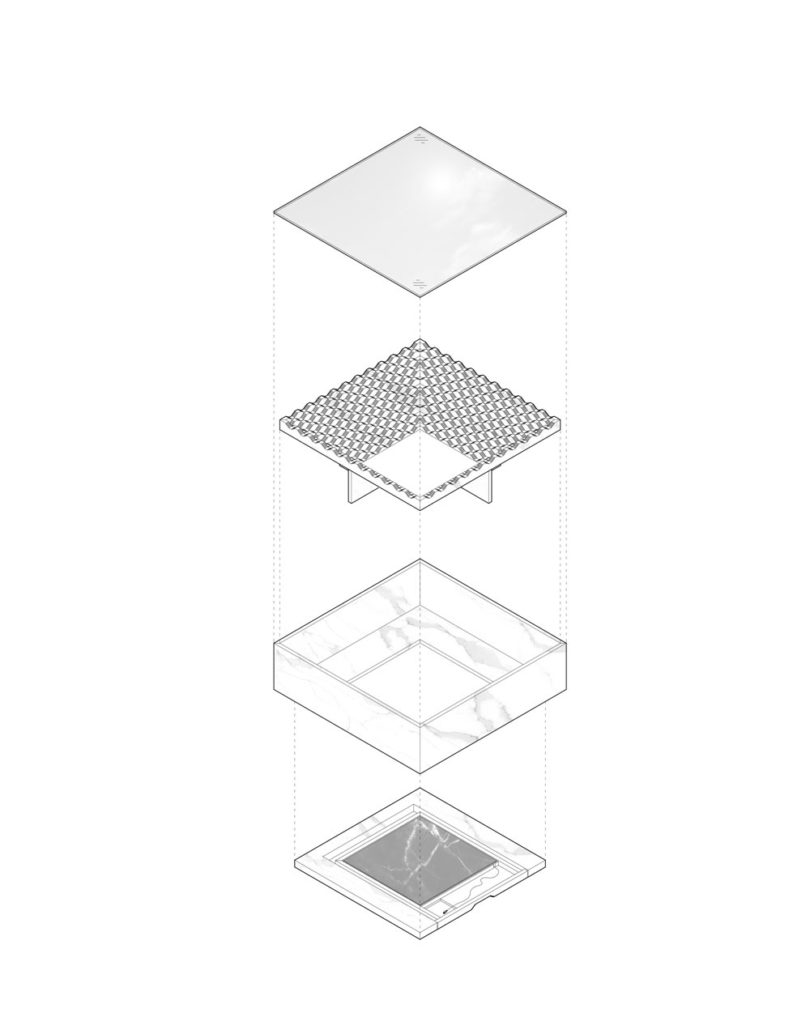

For Wallpaper* Handmade 2018 this past April, London-based Coffey Architects and Spanish surface manufacturer COMPAC partnered together to design and present the Stepwell Table, a coffee table inspired by India’s geometrical Chand Baori well. By using COMPAC’s highly advanced fabrication processes on their marble-like engineered quartz, they were able to achieve the intricate stepped look seen on the four sides of the table. The design and fabrication process was a joint effort between both companies and for this month’s Deconstruction, they’re taking us through the journey of how it all came together. Take a look.

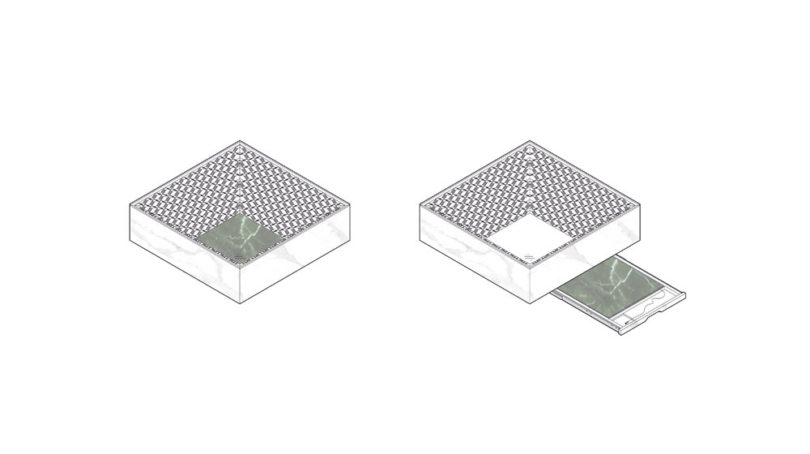

The table is inspired by the Chand Baori – the 800 A.D. Indian stepwell dedicated to the goddess of joy and happiness. From the outside, the table appears like a monolithic slab of marble. On the inside, however, the beautifully detailed stair geometry gives the impression of intricately carved stone. To emulate the striking, translucent water at the base of the original well, experimentation was made with the translucency of the COMPAC quartz by adding light to the bottom of the table.

The design of the table represents the origins of the stone material by creating something that looks like it is carved out of a solid piece.

The Stepwell Table is not just about the surface, but the space within it. It is a miniature architecture inside a table.

The elements of the table were carefully designed in collaboration with COMPAC.

Easy access to the light source is allowed via a drawer in the base. This also means that the translucent COMPAC Ice of Genesis quartz panel can be changed to another colour or material if required.

Design meeting at COMPAC HQ in Gandia, Spain. Coffey Architects presenting the concept.

Design meeting at COMPAC HQ in Gandia, Spain. Coffey Architects talking through the design of the table.

Design meeting at COMPAC HQ in Gandia, Spain. Presentation of the concept.

Design meeting at COMPAC HQ in Gandia, Spain. Presentation of the concept and discussing the manufacturing process.

Design meeting at COMPAC HQ in Gandia, Spain. COMPAC and Coffey Architects discussing choice of material and manufacturing of the table.

Factory walk-through COMPAC HQ in Gandia, Spain. Exploring the manufacturing processes.

Design meeting at COMPAC HQ in Gandia, Spain. Understanding the possibilities of light through the material.

Factory walk-through AT COMPAC HQ in Gandia, Spain. Coffey Architects learning about the manufacturing processes.

Factory walk-through COMPAC HQ in Gandia, Spain. Coffey Architects exploring the manufacturing processes.

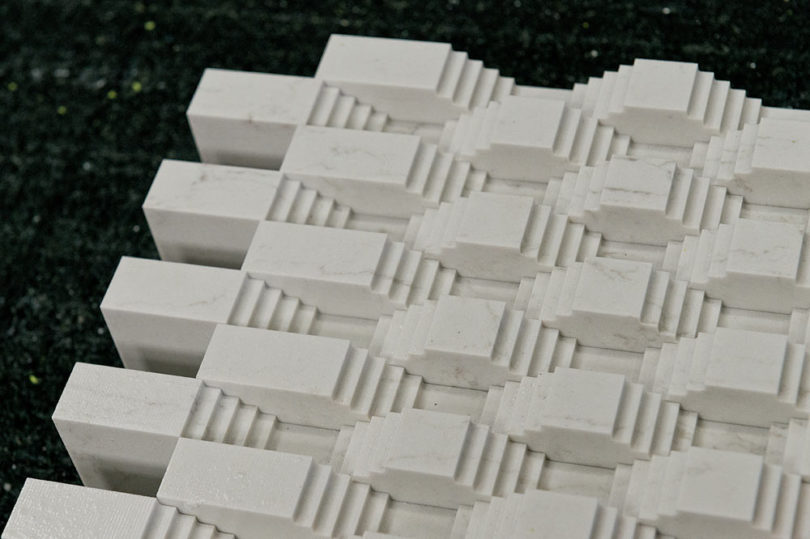

Precision was key in the manufacturing of the table.

The Stepwell Table was produced at the COMPAC HQ in Gandia, Spain.

First mock-up/prototype of the table.

The stairs consist of multiple 20mm layers of COMPAC quartz put together as one. Every step is 5mm long and 3.5mm high.

Water is very important in the production of the material, hence we wanted the concept of the Stepwell Table to have a close connection to water.

Finished interior of the table.

Finished interior of the table.

Finished table with the light off.

Finished table with the light on.

from Design MilkDesign Milk https://design-milk.com/how-coffey-architects-designed-the-stepwell-table-with-compacs-engineered-quartz/

No comments:

Post a Comment