We’ve followed Rhode Island based design firm Studio DUNN for a number of years now, appreciating the attention to detail and solid craftsmanship found in their furniture and lighting collections. One of which is their Architect’s Collection, a series of modern stools and a cafe table that give a modern spin to early 19th century task furniture used by architects and engineers. Today, the studio takes us on a behind-the-scenes look at how their Architect’s Stool with Back was conceived and how they make it in-house with hand-built components in this month’s Deconstruction.

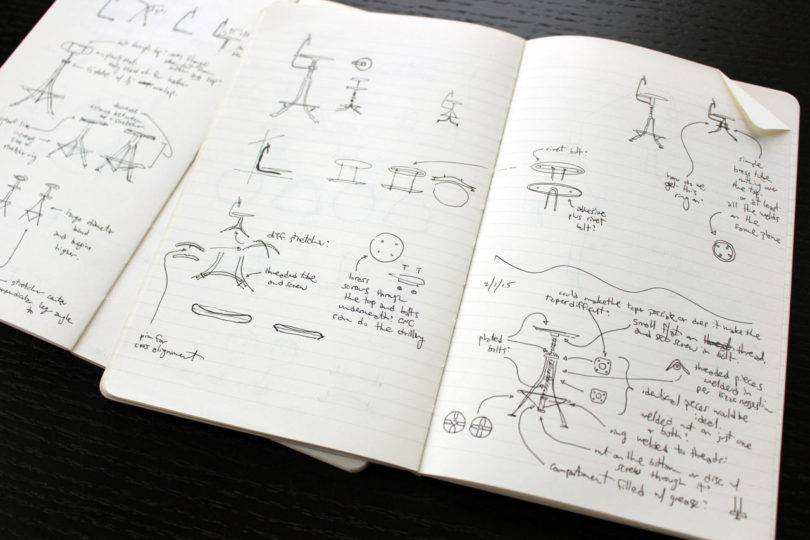

01 Sketching – It all starts with a sketch. I tend to fill up sketchbooks at a pace of one per month. When developing a new design, I have to consider the materials’ properties and their capabilities and limitations. My design process varies depending on what I’m designing. In this case, I tried to work out as much on paper as I could.

02 Sketch Modeling – Next I tinkered with models and prototypes to refine elements that I couldn’t fully see on paper.

03 CAD Modeling – I translated the physical models into rough 3D models. This allows me to refine the details and analyze small variations next to each other.

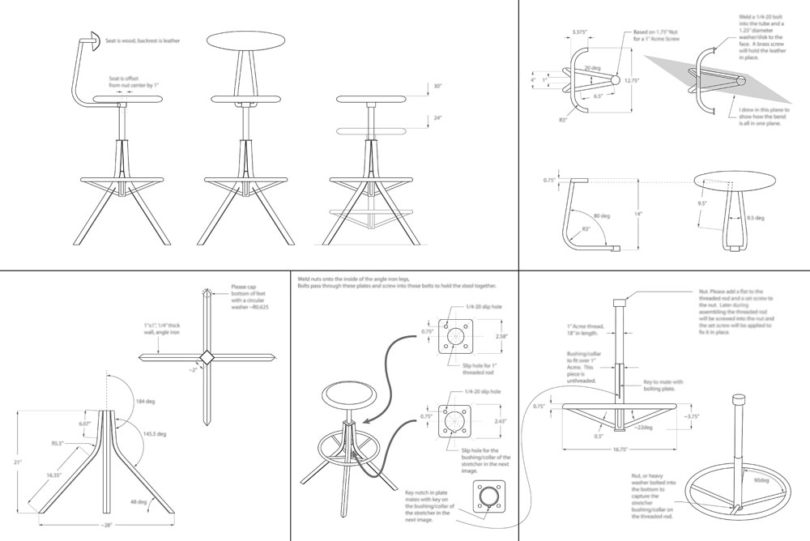

04 Sampling P1 – After refining the design, we record the manufacturing specifications.

05 Sampling P2 – Then we work with our local manufacturing partners to produce a full scale, working sample.

06 Evaluate – It’s nice to get it right on the first try, but more often than not, this stage of the design process requires some trial and error to determine what looks and works best and make modifications.

07 Production P1 – After everything has been sampled and approved, our first production batch can be fabricated. Many fabrication processes are used, including cutting, rolling, bending, and welding.

08 Production P2

9 Finishing P1 – The fabricated parts are sanded, then we apply a finish to protect them from corrosion.

10 Finishing P2

11 Machining – For this design, we also machine a handful of detail components from solid brass.

12 Quality Control – Every component goes through a scrupulous quality inspection to ensure the parts and finishes are up to snuff.

13 Assembly – The parts are assembled to make the completed stool design.

14 Stool Seats – The wood components (the stool seats and the tabletops) are turned in our woodshop.

15 Leather Sling Back P1 – The leather backrests are a very thick leather mounted with brass screws, which do not touch the tubular metal frame. The backrest conforms to the user when they lean back into the stool.

16 Leather Sling Back P2

17 Elevating Footrest – One component that makes these stools really unique is the elevating footrest. When the stool seat is raised or lowered, the footrest travels with it, maintaining a comfortable distance between the two.

18 Architect’s Stool with Back – Completed pieces. (Left and Right) White Oak Seat with Black Leather Backrests, Blackened Steel and Brass details. (Center) Walnut Seat with Chestnut Leather Backrests, Blackened Steel and Brass details.

20 Architect’s Stools – Completed pieces. White Oak with Blackened Steel and Brass details.

from Design MilkDesign Milk https://design-milk.com/studio-dunn-shares-the-design-process-of-the-architects-stool/

No comments:

Post a Comment