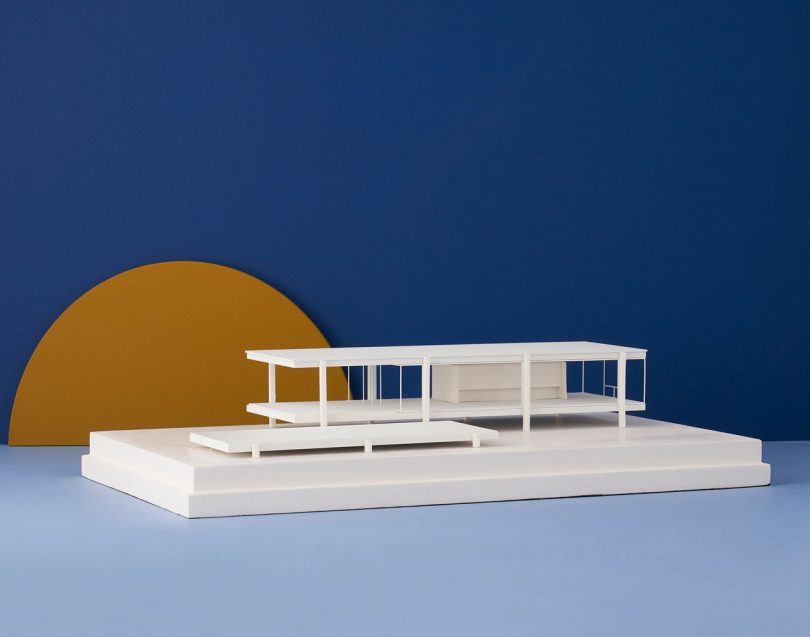

We immediately fell for UK-based Chisel & Mouse’s architectural sculptures after featuring their three-dimensional Cityscapes earlier this year. We liked them so much, we included their plaster wood 3D print model of the iconic Farnsworth House in one of our recent gift guides. The modernist model is still one of our favorites so we asked Chisel & Mouse to take us behind the scenes for this month’s Deconstruction to see just how much work is involved in bringing the architectural masterpiece to life.

First we draw the CAD model in SketchUp. Here it is in it’s exploded form. From this drawing we can 3d print parts, mould the base and cut the wood to scale.

We prepare the wood used for the walls and roof. Cut out the metal etching used for the window frames and door. The base is made in plaster, so we create a silicon mould and pour our beloved jesmonite – a plaster heavy with resin and wonderful to work with. Once we have our parts ready for assembly they are sprayed uniform white.

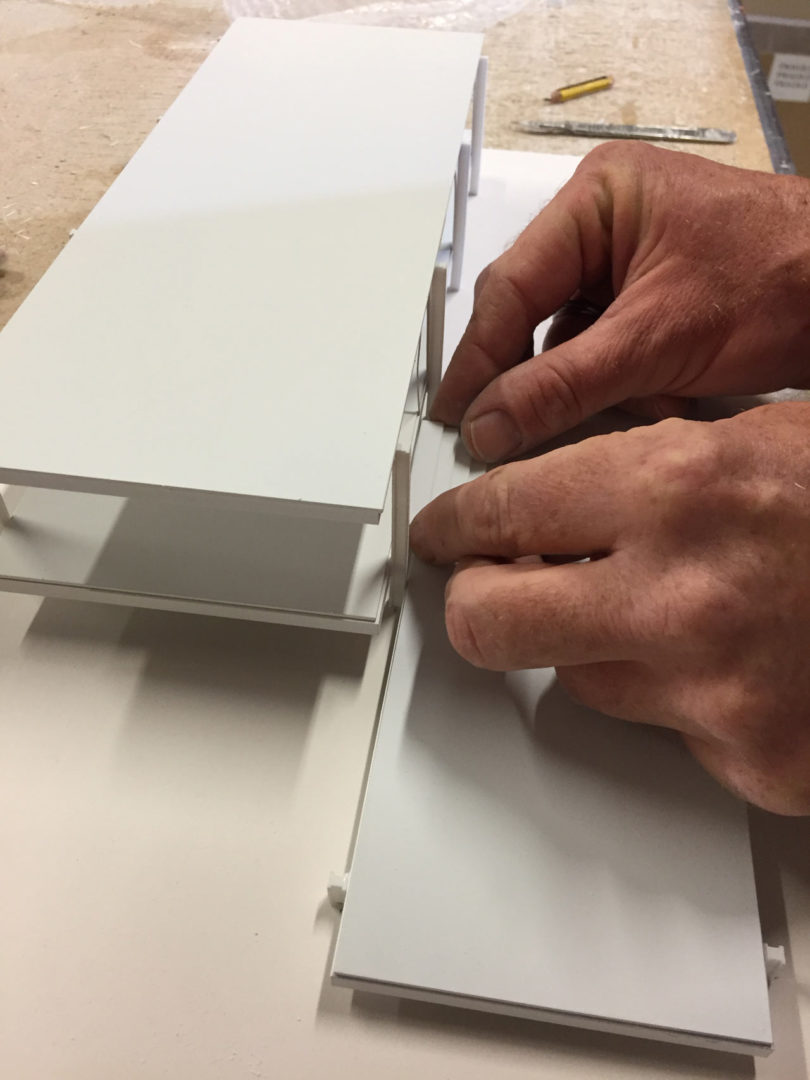

Once the parts are dry, the painstaking job of assembly begins. It takes several days to bring the model parts together, like an Airfix kit the model starts to come to life.

After an elapsed time of four days the model is finally complete and ready for delivery.

from Design MilkDesign Milk https://design-milk.com/how-chisel-mouse-crafts-a-3d-model-of-the-iconic-farnsworth-house/

No comments:

Post a Comment